Bifogade filer

Prenumeration

Climeon’s ORC-based waste heat recovery system to boost energy efficiency on world’s largest methanol-fueled cement carrier

Repeat Order Underscores Successful Cooperation

Climeon has received a repeat order from NovaAlgoma Cement Carriers (NACC) to supply its HeatPower 300 waste heat recovery system for a second cement carrier. The vessel, which will be built at Zhejiang Xinle Shipbuilding Co. in China, is scheduled for delivery in 2027. This follow-up project reflects strong, ongoing cooperation between Climeon, NovaAlgoma, and the shipyard, and underscores a shared commitment to advancing energy efficiency and reducing emissions in the cement shipping segment.

“Given the strong collaboration and positive progress on our first project with Climeon, it was an easy decision to continue the partnership on this next vessel,” said Vincenzo Romeo, CEO of NovaAlgoma Cement Carriers. “Climeon’s waste heat recovery technology brings real value to our vessels—both commercially and environmentally.”

World’s Largest Cement Carrier Powered by Green Methanol

Taking the next step in low-emission vessel design, this second ship in the series will operate exclusively on green methanol—making it the world’s largest cement carrier powered by renewable fuel. The 38,000-ton pneumatic cement carrier is expected to reduce CO₂ emissions by more than 60% compared to conventional vessels, translating to approximately 180,000 tons of CO₂ avoided over 10 years of operation. This reduction is made possible through the combined impact of clean fuel and energy efficiency technologies, including Climeon’s waste heat recovery system.

“We’re proud to support the development of such a pioneering vessel and to contribute to its long-term environmental performance,” said Fredrik Thoren, EVP and Head of Marine at Climeon. “We’re grateful for the continued trust placed in our technology and team by NovaAlgoma as we work together toward more sustainable shipping.”

Waste Heat Recovery for Enhanced Energy Efficiency on Board

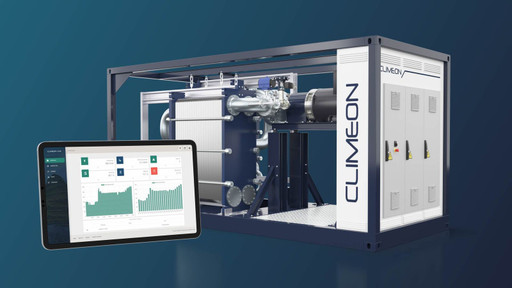

The HeatPower 300 will generate up to 300 kW of carbon-free electricity onboard by converting low-temperature waste heat from engine cooling water and exhaust gases. This improves fuel efficiency, reduces emissions, and supports compliance with tightening environmental regulations—while delivering real economic value over the vessel’s lifetime.

Collaboration Key to Project Success

Zhejiang Xinle Shipbuilding Co. in China continues to play a central role in integrating advanced sustainability features on this new series of cement carriers. Effective cooperation between Climeon, the shipyard, and vessel owner NovaAlgoma has been important in successfully aligning the HeatPower 300 system with the vessel’s design and construction timeline.

Supporting the Transition to Low-Emission Shipping

This second order reinforces Climeon’s role as a trusted supplier for large-scale, low-emission vessels and showcases how collaborative innovation between shipowners, yards, and technology providers can accelerate the shift to sustainable maritime transport.